Printing technology

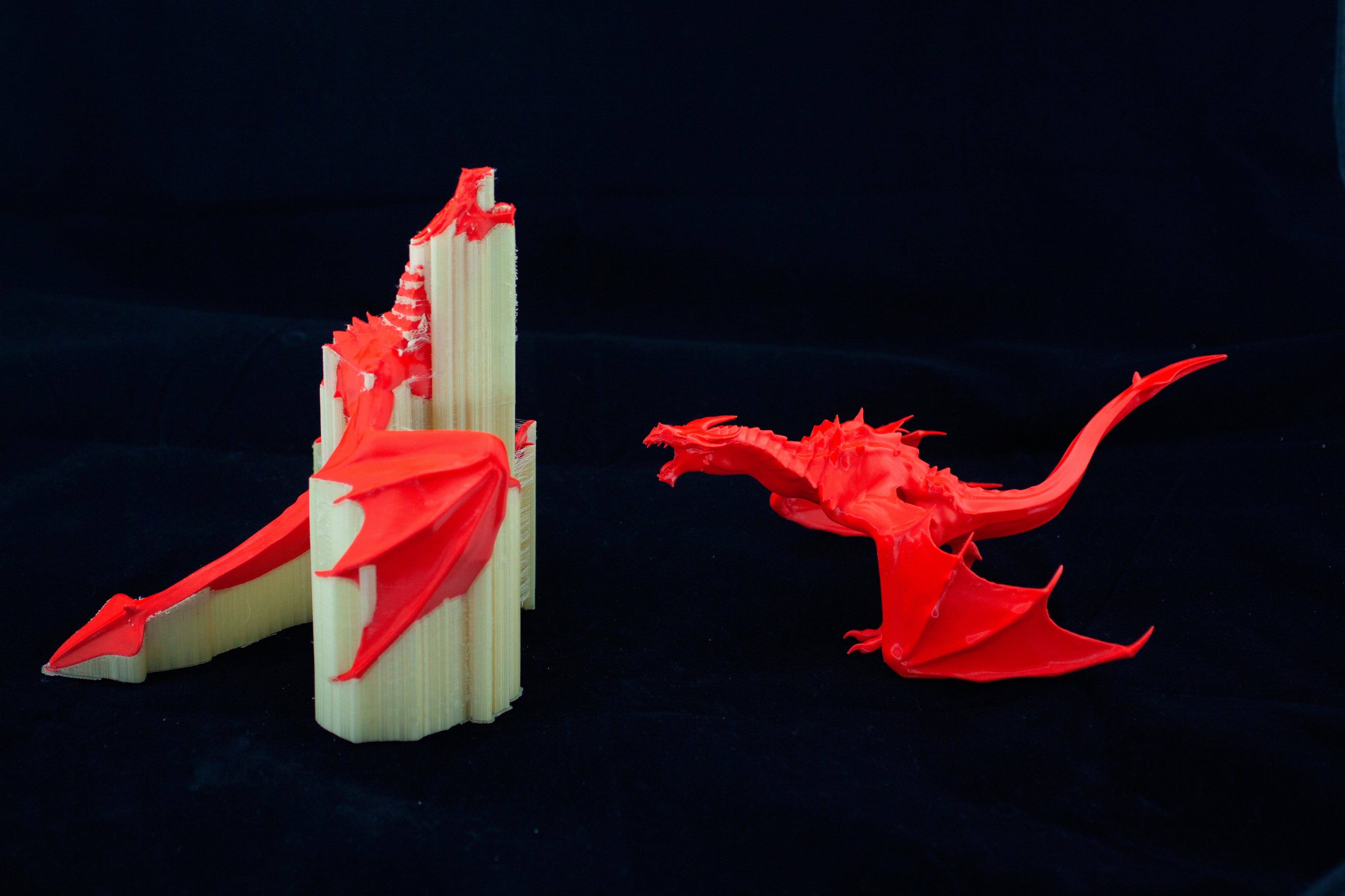

Fused Filament Fabrication (FFF)

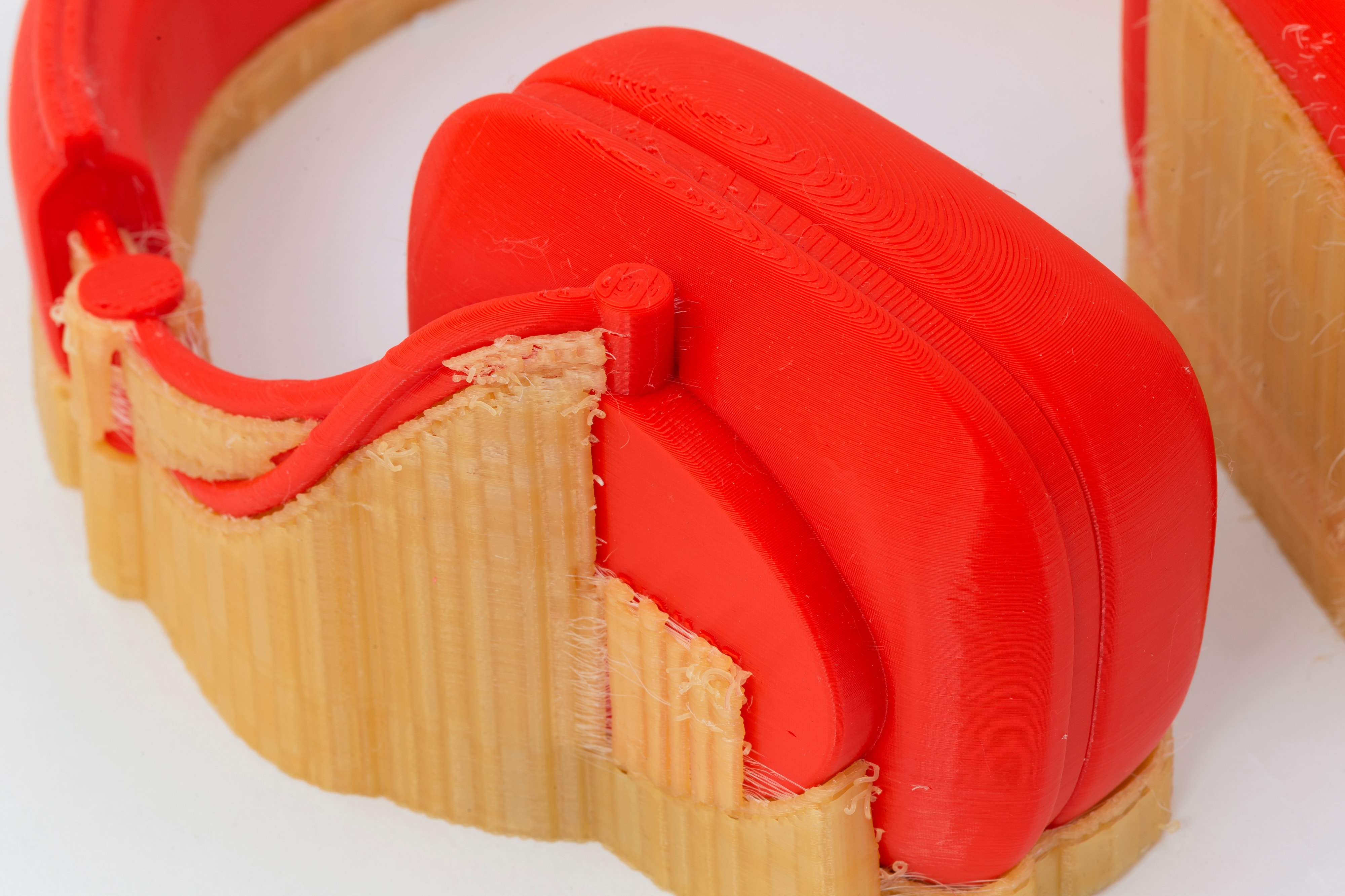

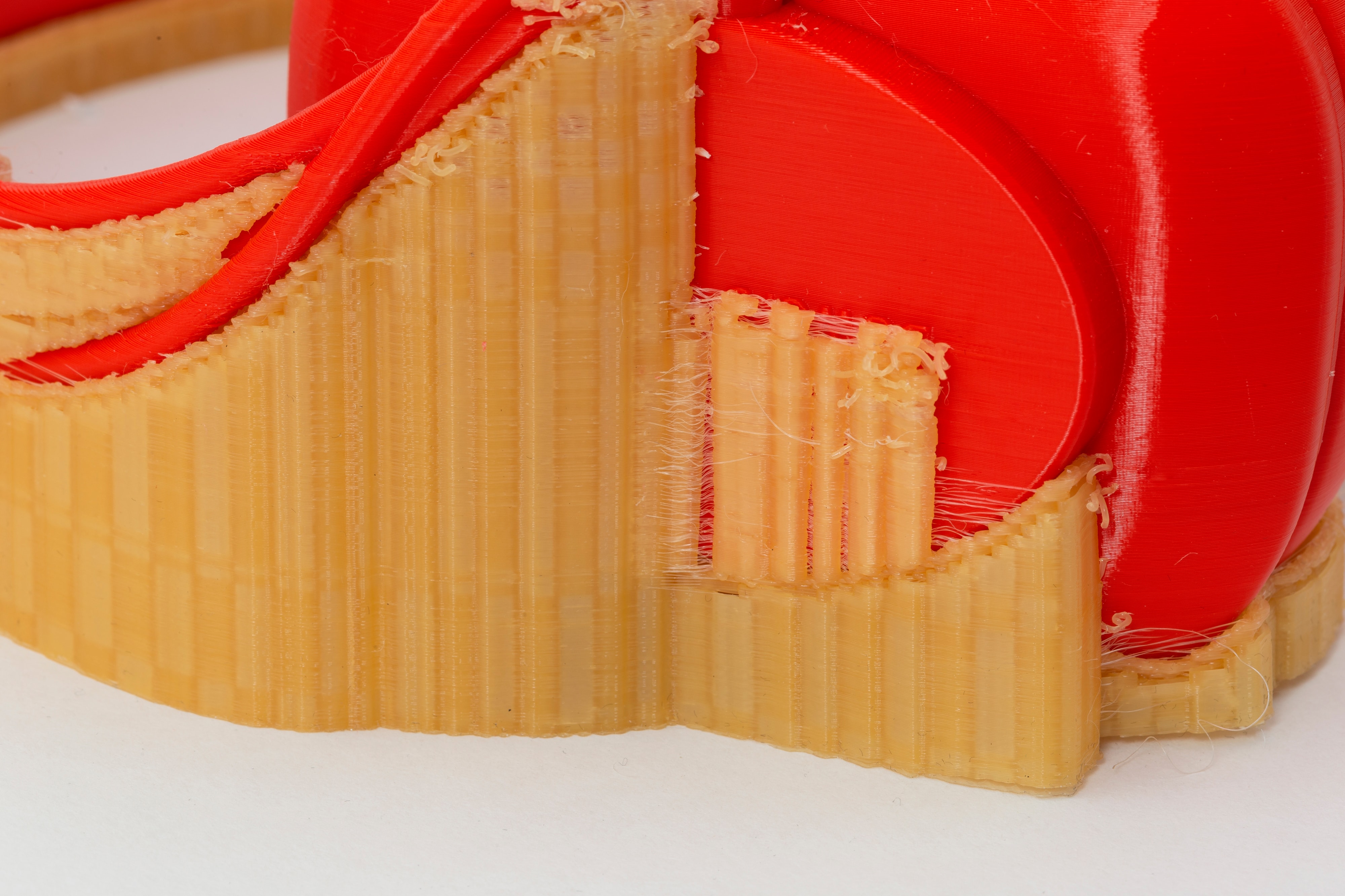

Nozzle switching technology

Jet SwitchTM

(2 nozzles at 1 extruder)

Build Volume

200 x 200 x 210 mm

(7.9 x 7.9 x 8.3 inch)

Extruder maximum printing

temperature

410 ºC (770 F)

Heated bed maximum temperature

150 ºC (302 F)

Print speed

up to 100 cm3/h

Minimum Layer Thickness

10 microns (0.01 mm)

Layer Resolution

0.01 – 0.8 mm (depending on the

nozzle diameter)

Positioning Resolution

11 x 11 x 1.25 microns

Filament diameter

1.75 ± 0.1 mm

Nozzles diameter

0.2 – 0.8 mm (0.3 in start kit)

- A compact solution for complex tasks

- 2nd generation nozzle switching system (Jet Switch TM)

- Full support of the X Platform

Smart on the inside

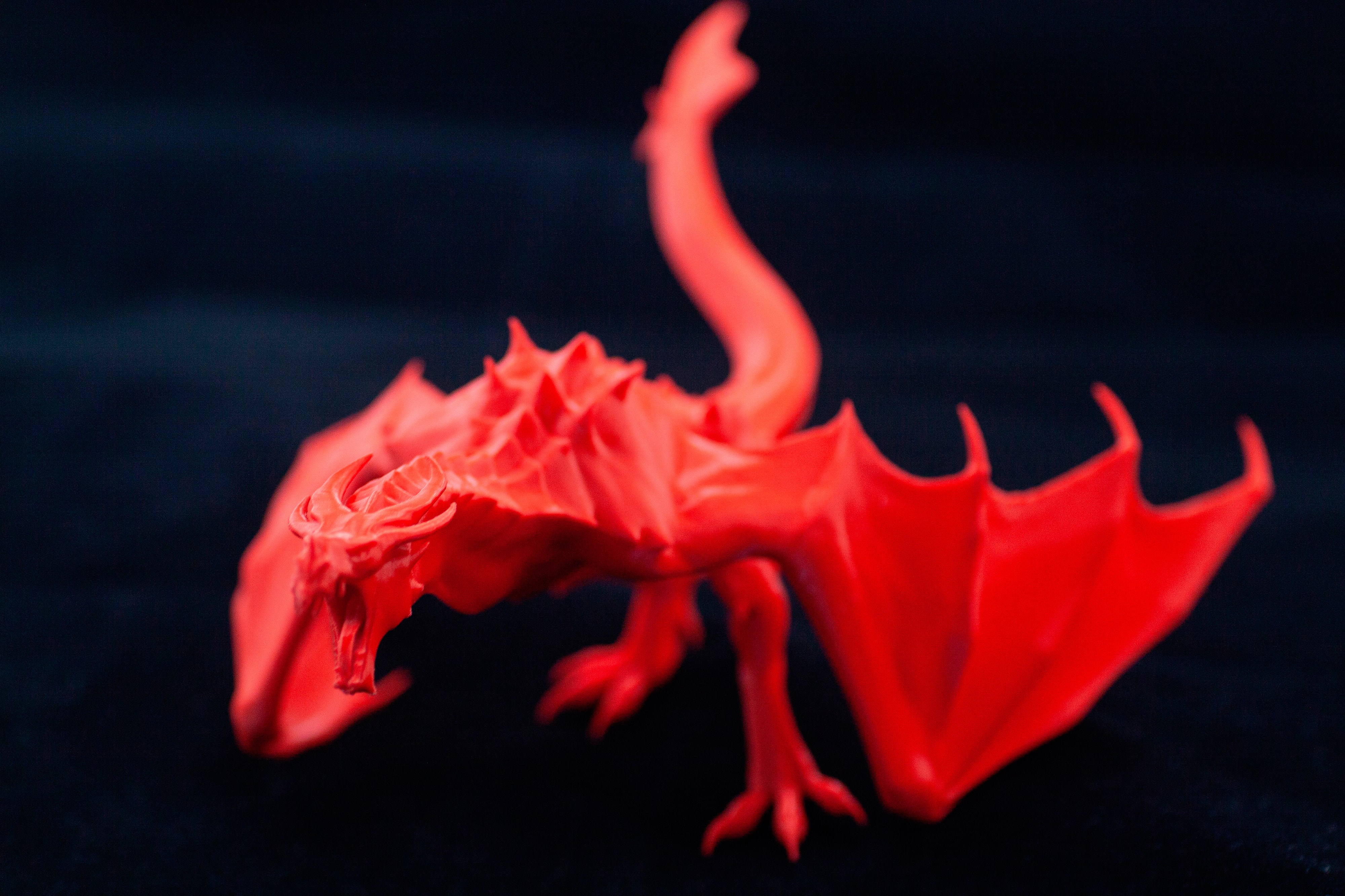

Fast printing with the highest quality

High repetitiveness of the end result

Compact and easy to use

High repetitiveness of the end result

Compact and easy to use

Printing control systems

Filament flow control system

Built-in encoder and algorithms monitor material feeding once every 20ms

End-of-filament sensor

Control of end of supply for plastic and automatic printing pause. This allows to save material and secure printing result

Temperature control

The radiator temperature sensor can prevent plastic from overheating in the “cold zone”

Layer time control

Allows to sustain the print quality even for the models with small printing layer/size

Delta Z control

The height delta between the nozzles is calculated automatically and is adjusted with up to 0.01mm precision in dual-material printing mode

Automatic first layer control

At the start of the printing process the nozzle to print-bed pressure (z-offset) is calculated automatically

Surface control

Control of surface warping and will pause the printing and save material in a case of printout delamination

Access over the network

Remote printing launch and control of the 3DP farm though Polygon X software

— Swich time ~ 0.5 sec

— Repetitive nozzle alignment of < 1 μm

— Special flap for clean printing

State-of-the-art nozzle switching system.

for PRO-series printers.

for PRO-series printers.

For PRO-series printers

Enhanced with Polygon X software algorithms

in allows to achieve top-of-the-industry quality.

Specs

Printing

Mechanics

Casing

Aluminium composite

Frame

Steel

Heated bed construction

Aluminium, glass

Guides

XY rail (steel)

Z cylindrical (steel)

Aluminium composite

Frame

Steel

Heated bed construction

Aluminium, glass

Guides

XY rail (steel)

Z cylindrical (steel)

Electricity

Networking

220 ± 15%, 50 Hz

(option 110 ± 15%, 60 Hz)

Maximum Power Consumption

400 W

Interfaces

Ethernet, USB 2.0 (Flashdrive

in start kit)

220 ± 15%, 50 Hz

(option 110 ± 15%, 60 Hz)

Maximum Power Consumption

400 W

Interfaces

Ethernet, USB 2.0 (Flashdrive

in start kit)

Printing Materials

Formax (ABS + CF), Ultrax (PA + CF), PEEK, PA, PC, TPU, TPE, PP, ASA, SBS, PETG, ABS, PLA, PVA, HIPS and others

Phisical Characteristics

Printer dimensions

In box 700 x 500 x 540 mm

Without box 490 x 390 x 430 mm)

Weight

23 kg (17.5 kg)

In box 700 x 500 x 540 mm

Without box 490 x 390 x 430 mm)

Weight

23 kg (17.5 kg)

Software

Software

Polygon X

File Types

*.stl, *.plgx

Polygon X

File Types

*.stl, *.plgx

Features

Primary systems

Filament Flow Control

End-of-Filament Sensor

First Layer Control

Built-in Profile System

Network Printing

Additional features

Filament drying mode

Printer status notification system

Auto-control workability of all systems

Surface print control system

Table Leveling

Active leveling

Filament Flow Control

End-of-Filament Sensor

First Layer Control

Built-in Profile System

Network Printing

Additional features

Filament drying mode

Printer status notification system

Auto-control workability of all systems

Surface print control system

Table Leveling

Active leveling