The ability to apply the FFF machines in the critical business areas, like printing of functional parts, is defined by the qualities of material used.

This obvious though has inspired us to invest our efforts and knowledge into the development of the material with unprecedented durability, thermal stability and resistance. At the same time we have set a goal of having a material applicable for FFF without making changes to the machine itself.

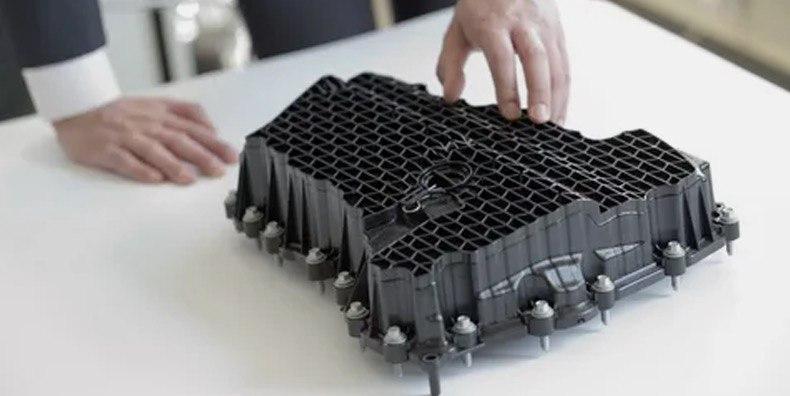

Ultrax - a composite engineering material built from PA6 and carbon fiber - is the result of these efforts.

Ultrax does not require any finishing after printing, but at the same time it can change it’s physical appearance from the application of tars. Damage resistance, tensile force, elastic modulus are just three of multiple characteristics of the finished printout that were significantly enhanced vs traditional ABS.

And it does not require a heated chamber or additional draft shielding – simply install the steel nozzle supplied by PICASO 3D and enjoy all the advantages.

Specs

297 ºC

Build plate temperature

45 ºC

Glass transition temperature

60 ºC

Support materials

PVA (soluble)

UltraX (removable)

1.75 ± 0.1 mm

Fiber mass fraction

27 %

Color

Black

Spools

750 g

1.23 g/cm3

Impact strength Charpy (without notch)

45 kJ/m2

Tensile strength (XY-axis)

80 MPa

Tensile modulus (XY-axis)

3.77 GPa

Flexural strength (bend strength)

102 MPa

Modulus of elasticity to bend

3.97 GPa

Maximum bending load

1.70 kN

Tensile strength (ZX-axis)

30.05 MPa

Tensile modulus (ZX-axis)

2619 MPa

Compressive strength

117.8 MPa

Compression modulus of elasticity

2.244 GPa

Maximum compression load

17.1 kN

Elongation at break

5 %

Shrinkage

0.3 – 0,4 %